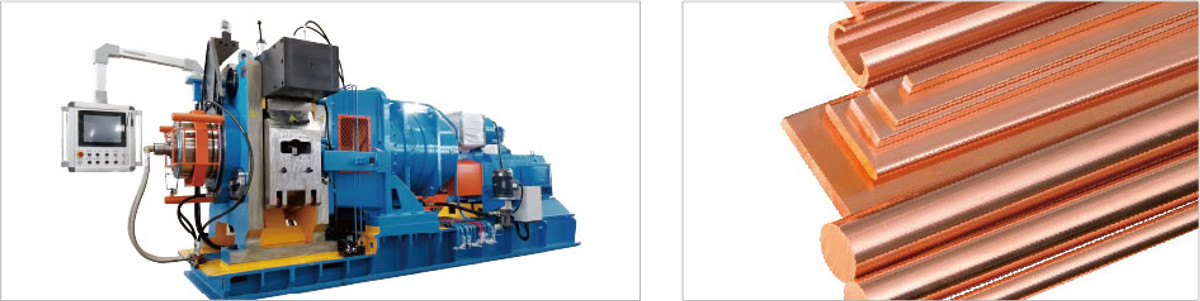

Kuenderera mberi Extrusion Machinery

Zvakanakira

1, deformation yepurasitiki yetsvimbo yekudyisa pasi pesimba rekukwesha uye tembiricha yakakwira iyo inobvisa kukanganisa kwemukati mutsvimbo pachayo zvachose kuti ive nechokwadi chekupedzisira zvigadzirwa zvine mashandiro akanaka echigadzirwa uye yakakwira dimensional kurongeka.

2, kwete preheating kana annealing, yakanaka mhando zvigadzirwa zvinowanikwa neextrusion process ine yakaderera simba rekushandisa.

3, ine saizi imwe chete yekudyisa tsvimbo, muchina uyu unogona kuburitsa huwandu hwakakura hwezvigadzirwa nekushandisa mafiro akasiyana.

4, mutsara wese uri nyore uye nekukurumidza unoshanda pasina chero basa rinorema kana kusvibiswa panguva yeextrusion.

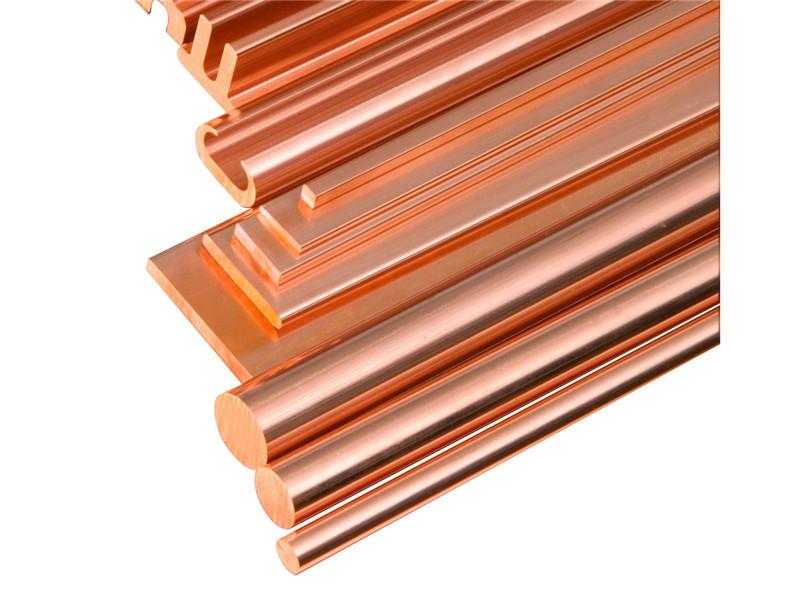

Kudyisa tsvimbo yemhangura

1.Kugadzira mhangura flat wire, duku mhangura busbar uye kumativi waya

| Model | TLJ 300 | TLJ 300H |

| Main Motor Power(kw) | 90 | 110 |

| Kudyisa tsvimbo dia.(mm) | 12.5 | 12.5 |

| Max.upamhi hwechigadzirwa (mm) | 40 | 30 |

| Flat Wire Cross-Sectional | 5-200 | 5 -150 |

| Kubuda (kg/h) | 480 | 800 |

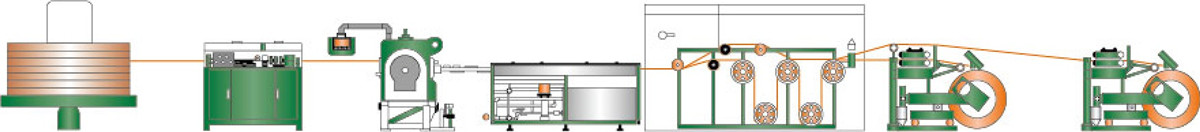

Production Line Layout

Pay-off Pretreatment Extrusion Machine Cooling Sys.Dancer Take-up Machine

2.Kugadzira mhangura busbar, mhangura yemhangura uye mbiri yemhangura

| Model | TLJ 350 | TLJ 350H | TLJ 400 | TLJ 400H | TLJ 500 | TLJ 630 |

| main mota simba (kw) | 160 | 200 | 250 | 315 | 355 | 600 |

| kudyisa tsvimbo dia.(mm) | 16 | 16 | 20 | 20 | 25 | 30 |

| max.upamhi hwechigadzirwa (mm) | 100 | 100 | 170 | 170 | 260 | 320 |

| chigadzirwa tsvimbo dia.(mm) | 4.5-50 | 4.5-50 | 8-90 | 8-90 | 12-100 | 12-120 |

| chigadzirwa muchinjika-chikamu nzvimbo(mm2) | 15-1000 | 15-1000 | 75-2000 | 75-2000 | 300-3200 | 600-6400 |

| kubuda (kg/h) | 780 | 950 | 1200 | 1500 | 1800 | 2800 |

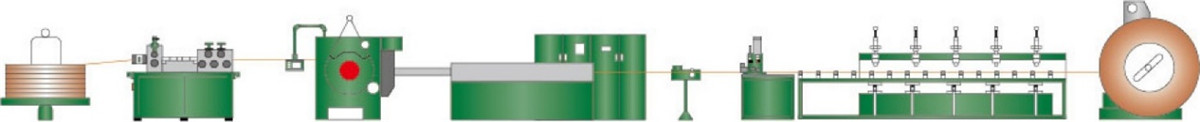

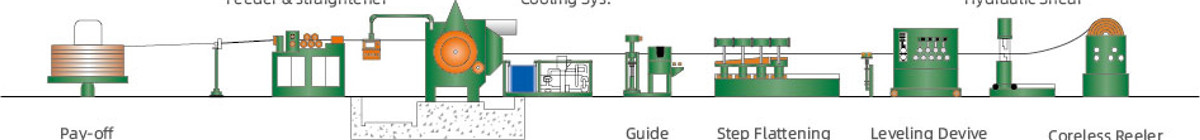

Production Line Layout

Pay-off Feeder & straightener Extrusion Machine Kutonhodza Sys.Kureba Counter Chigadzirwa Bhenji Kutora-up Machine

3. Kuita bhasikoro yemhangura, tambo yemhangura

| Model | TLJ 500U | TLJ 600U |

| main mota simba (kw) | 355 | 600 |

| kudyisa tsvimbo dia.(mm) | 20 | 30 |

| max.upamhi hwechigadzirwa (mm) | 250 | 420 |

| max.hupamhi kune ukobvu reshiyo | 76 | 35 |

| chigadzirwa ukobvu(mm) | 3-5 | 14-18 |

| kubuda (kg/h) | 1000 | 3500 |

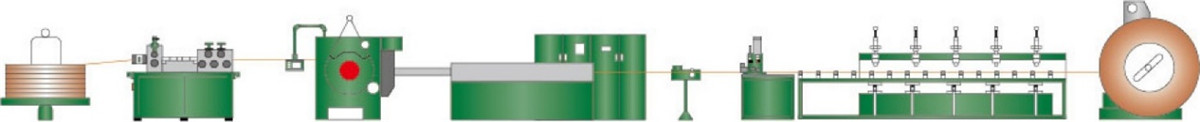

Production Line Layout

Copper alloy tsvimbo yekudyisa

Kunyorera commutator conductor, brass isina chinhu, phosphor copper tsvimbo, lead frame strip, njanji yekubata waya nezvimwe.

| TLJ 350 | TLJ 400 | TLJ 500 | TLJ 630 | |

| zvinhu | 1459/62/63/65 brass cu/Ag (AgsO.08%) | phosphor mhangura (Pso.5%) cu/Ag (AgsO.3%) | magnesium mhangura (MgsO.5%)simbi mhangura (Feso.l% | magnesium mhangura(MgsO.7%)/Cucrzr |

| kudyisa tsvimbo dia.(mm) | 12/12.5 | 20 | 20 | 25 |

| max.upamhi hwechigadzirwa (mm) | 30 | 150 (simbi yendarira yesirivha) | 100(lead frame strip:) | 320 |

| chigadzirwa tsvimbo dia.(mm) | phosphor copperball: 10-40 | magnesium copperrod: 20-40 | magnesium copperrod: 20-40 | |

| kubuda (kg/h) | 380 | 800-1000 | 1000-1200 | 1250/850 |

Production Line Layout

Pay-off Feeder & straightener Extrusion Machine Kutonhodza Sys.Length Counter Take-up Machine

Aluminium tsvimbo yekudyisa

Kunyorera waya yakapfava, bhawa yebhazi, uye profiled conductor, round tube, MPE, uye PFC Tubes.

| Model | LLJ 300 | LLJ 300H | LLJ 350 | LLJ 400 |

| main mota simba (kw) | 110 | 110 | 160 | 250 |

| kudyisa tsvimbo dia.(mm) | 9.5 | 9.5 | 2*9.5/15 | 2*12/15 |

| max.hupamhi hwechigadzirwa chewaya yakatsetseka (mm) | 30 | 30 | 170 | |

| flat wire chigadzirwa muchinjiko-chikamu Nzvimbo(mm2) | 5-200 | 5-200 | 25-300 | 75-2000 |

| round tube dia.(mm) | 5-20 | 5-20 | 7-50 | |

| flat chubhu yakafara (mm) | - | ≤40 | ≤70 | |

| waya yakatsetseka /chubhu Kubuda (kg/h) | 160/160 | 280/240 | 260/260 | (600/900)/- |

Production Line Layout

Pay-off straightener Ultrasonic kuchenesa Kutonhora Sys Dancer Take-up Machine

Mufananidzo 217282